- Home

- Custom Service

What we do

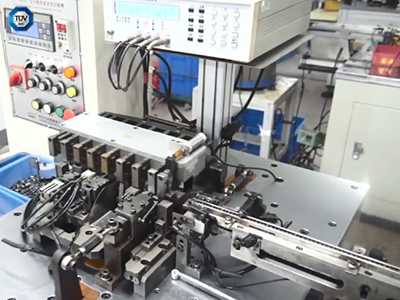

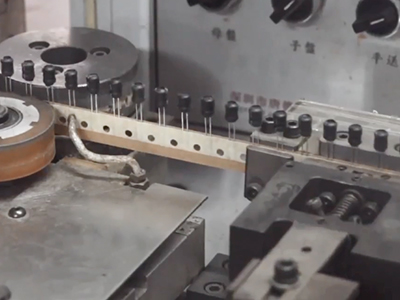

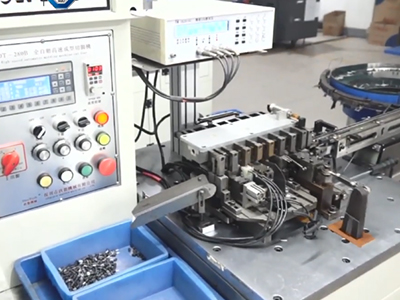

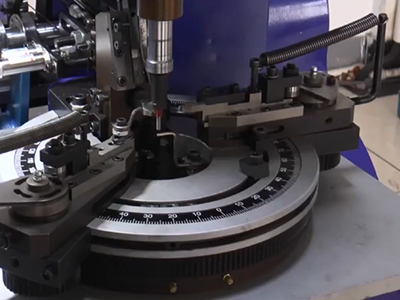

Ever since our establishment in 1989, Southern Group has been focusing on the production of various types of inductive coils and have developed inductors, electronic transformers, wire wound resistors, film resistors, filters, current fuses and several other series of high-quality electronic products. We have implemented a highly efficient and effective production and quality inspection process to ensure consistent product quality.

Materials purchasing

Before materials are allowed to enter our factory, we have specialized inspection personnel who perform sampling inspection and analysis on the materials. Any materials deemed unqualified will be promptly returned as a show that only qualified raw materials are used in our production processes.

During the production process, we will perform sampling inspection on each batch of products. If any products are found to not meet our standards, we will begin carrying out a complete inspection process. We will scrap entire batches of products if we suspect that they might be defective. We work extremely hard to ensure customers are satisfied with our products and quality inspection is of the utmost importance. Meanwhile, our workshops are overseen by a regular inspector to conduct secondary sampling inspection to reconfirm product quality.

Shipment

Before shipment, we will conduct full-scale sampling inspection and electrical performance. Any products with problems will be isolated and reported.

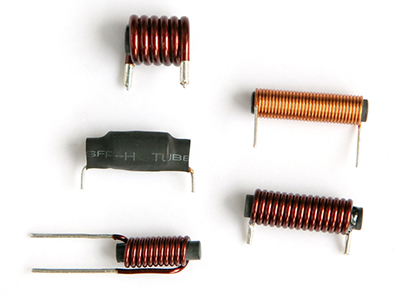

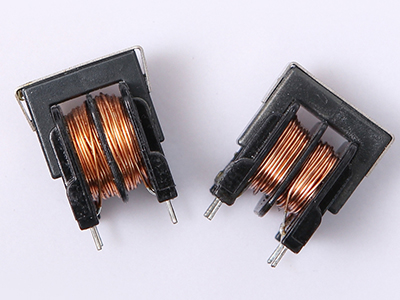

Differential Mode Choke Coil

Differential Mode Choke Coil Rod Core Choke

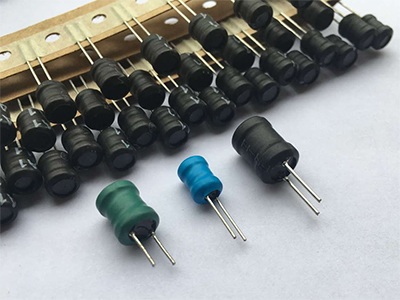

Rod Core Choke Rod Core Choke

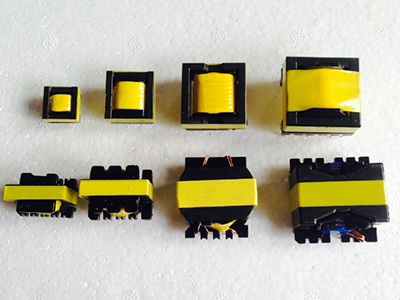

Rod Core Choke Electronic Transformer

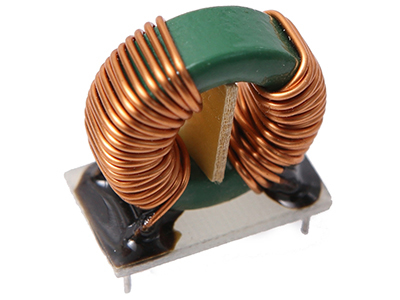

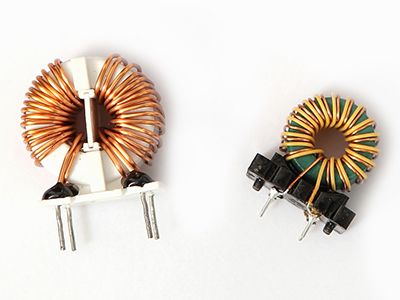

Electronic Transformer Common Mode Choke

Common Mode Choke Common Mode Choke

Common Mode Choke Common Mode Choke

Common Mode Choke Metal Shell Case Wire wound Resistor

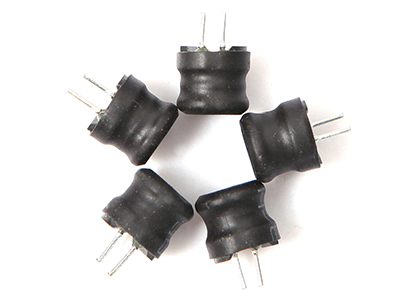

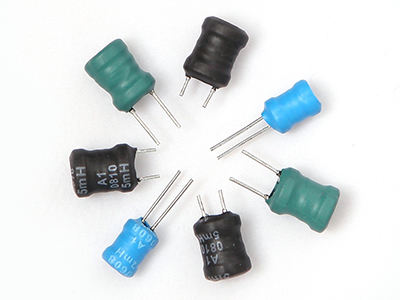

Metal Shell Case Wire wound Resistor Fixed Inductor

Fixed Inductor Fixed Inductor

Fixed Inductor Fixed Inductor

Fixed Inductor Metal Shell Wire Wound Resistor

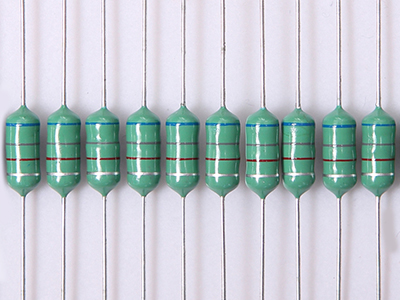

Metal Shell Wire Wound Resistor Axial Leaded Conformal Coated Inductor

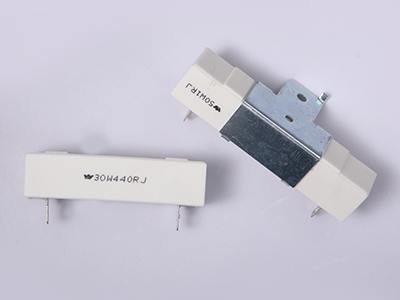

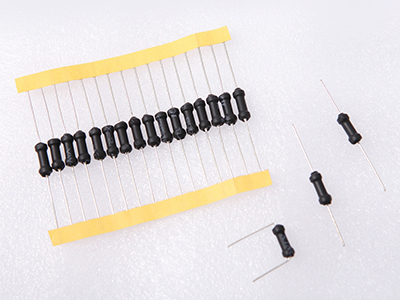

Axial Leaded Conformal Coated Inductor Ceramic Encased Wire Wound Resistor

Ceramic Encased Wire Wound Resistor Ceramic Encased Wire Wound Resistor

Ceramic Encased Wire Wound Resistor Ceramic Encased Wire Wound Resistor

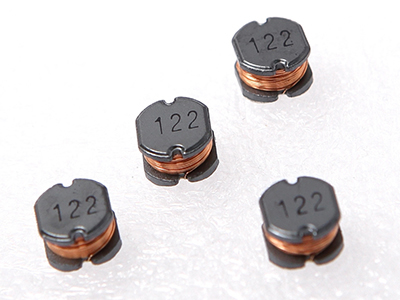

Ceramic Encased Wire Wound Resistor SMD Power Inductor

SMD Power Inductor SMD Power Inductor

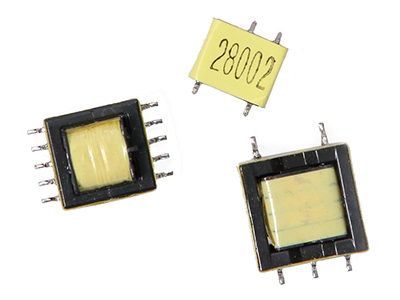

SMD Power Inductor High Voltage Transformer

High Voltage Transformer Axial Fixed Inductor, Leaded Inductor

Axial Fixed Inductor, Leaded Inductor