Resistor

As the most common electronic element, resistor is essential for each electrical circuit. Resistors are available in shapes and sizes, classified as standard static resistor and special variable resistor.

The following resistors are produced for clients by Southern Group. You can purchase directly or contact us to customize if you have such demands.

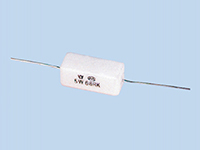

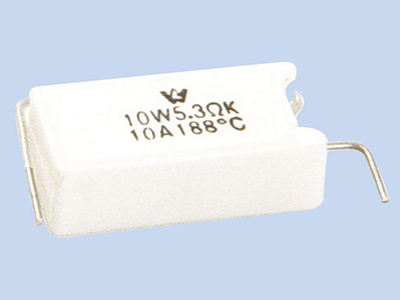

Wire wound resistor is used for current limiting, manufactured by winding metal wire around non-conducting material made core. The common materials for casing are ceramic, metal, etc.

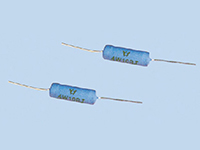

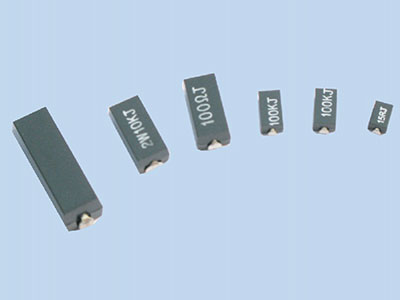

Thin film resistor is the common resistor type. This series resistor has different resistance layer on their ceramic substrates. Although this series resistors have similar appearance, their performances and manufacturing techniques are different.

Plenty of SMD resistors are used every day. They are square. Both ends of the resistor features a metal region, making it capable to be welded together with the PCB (printed circuit board).

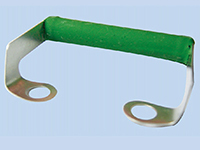

Milliohm resistor features a smaller resistance and it can be used in circuit for current sampling. Meanwhile, this milliohm resistor has stronger electricity conduction capacity and better heat resistance, helping to extend its life span.

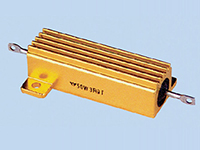

Fusible resistor is characterized by repeatable fuse, making it applicable to high temperature and high power conditions.

Resistors are various in types. But Southern Group has the ability to provide different custom resistors based on clients’ actual demands. If you also have such desires, and please contact us to customize.

Since 1989, Southern Group has been offering customers with custom resistors and produced different materials and types of resistors following their demands, including wire wound resistor, thin film resistor, fusible resistor, etc. Automatic equipment is applied for resistor production, with an annual output of up to 200 million. This ensures timely supply to meet customers’ demands. You are welcomed to contact us if you are looking for resistors.