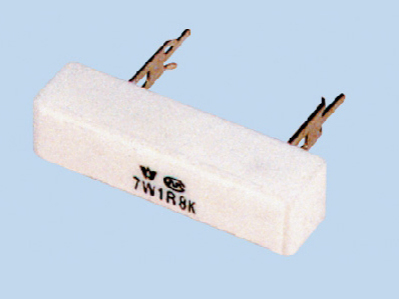

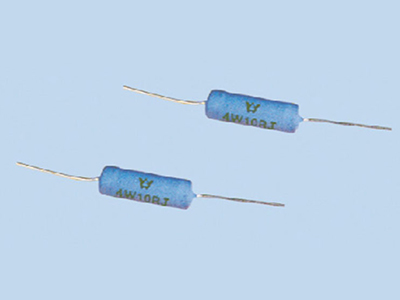

Wire Wound Resistor

Wire wound resistor is used for current limiting, manufactured by winding metal wire around non-conducting material made core. The common materials for casing are ceramic, metal, etc.

Please refer to the following wire wound resistors produced by Southern Group.

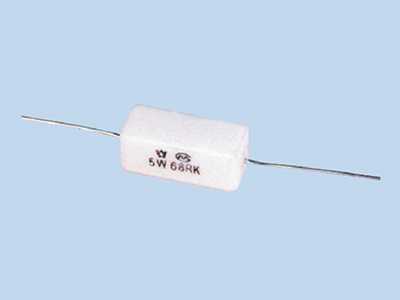

Southern Group supplied wire wound resistor adopts ceramic casing, featuring outstanding insulating property. Besides, it helps to enhance the heat dissipation performance of the resistor due to the low-temperature property of the ceramic surface under high temperature condition.

Southern Group provides different powers of wire wound resistors, including 2W, 7W, 10W, etc. In addition, special designs of size, resistance, power and shape are also available based on clients’ requirements.

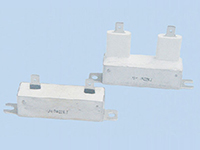

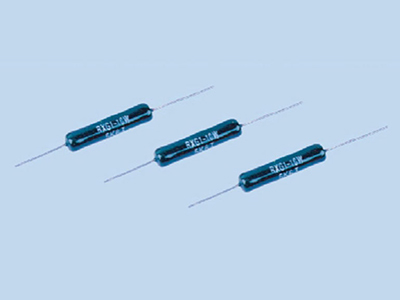

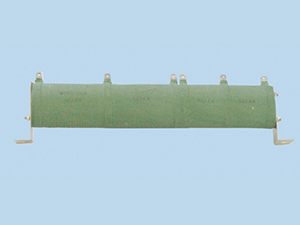

Enamel wire wound resistor is coated with hard burnt glass material - enamel. This coating can bear a high temperature of 350℃, making it widely applicable to auto electronics, household appliances, communication equipment, energy-saving lamp, automatic control device (like converter, etc.) and other fields.

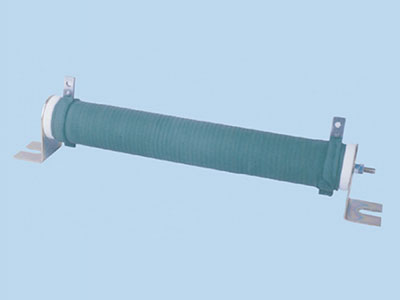

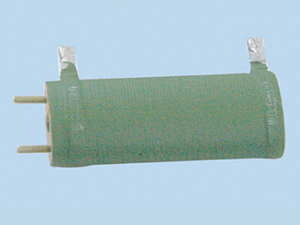

Coating wire wound resistor is composed of circular ceramic resistor, with heat resisting material coated wound wire. Thus it is widely used in automotive electronics, household appliances, communication equipment, energy-saving lamps, automatic control device (like converter) and other industries.

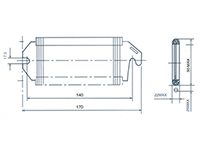

Aluminum Housed Chassis Mounted Wire Wound Resistor

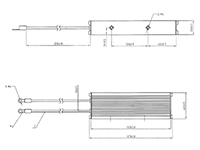

Aluminum Housed Chassis Mounted Wire Wound Resistor Aluminum Housed Metal Clad Braking Resistor

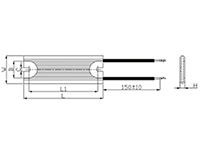

Aluminum Housed Metal Clad Braking Resistor Aluminum Shell Wire Wound Resistor(Side Slot)

Aluminum Shell Wire Wound Resistor(Side Slot) Aluminum Shell Wire Wound Resistor

Aluminum Shell Wire Wound Resistor Aluminum Shell Metal Film Resistor

Aluminum Shell Metal Film Resistor Aluminum Shell Wire Winding Resistor

Aluminum Shell Wire Winding Resistor Aluminum Shell Wire Wound Resistor

Aluminum Shell Wire Wound Resistor Aluminum Square Shell Wire Wound Resistor

Aluminum Square Shell Wire Wound Resistor Stainless Steel Wire Wound Resistor

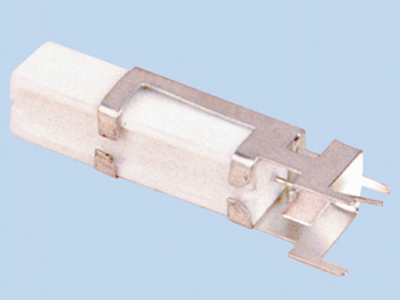

Stainless Steel Wire Wound Resistor Chip Resistor

Chip Resistor

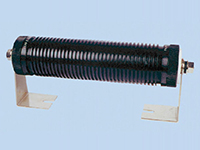

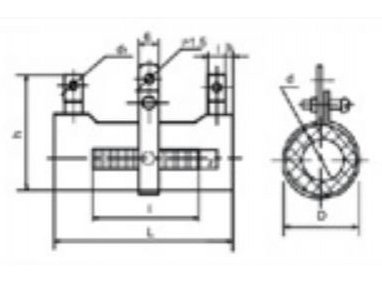

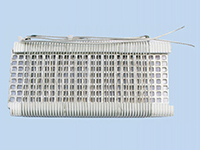

Open wire wound resistor is designed with a open structure, allowing this series resistors of better heat dissipation. It can still run stably even under long-term working conditions. This ensures you of extended operating time.

Our company mainly provides passive electronic components with over 30 years of experience. Shown above are some examples of our wire wound resistors, and we have a large number of products for you to choose from. Besides the specifications shown on this page, we also provide custom resistors and other passive components to meet your demands.

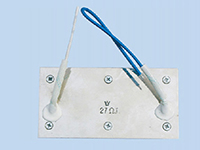

Plate Resistor

Plate Resistor Mini Plate Resistor

Mini Plate Resistor Resistor Module

Resistor Module